Electrical contacts play a seemingly simple yet critical role in electrical systems. They act as the interface between circuit segments, allowing the segments to connect and disconnect when necessary. Although this seems straightforward, the design of this connection requires extensive planning and consideration. If designed incorrectly, electrical contacts can exhibit excessive tarnishing, welding wear, mechanical degradation, or corrosive wear, which can result in a faulty connection. Contacts must be designed to minimize the occurrence of these failure modes, all while maintaining low contact resistance, minimal electrical noise, and reliable connection/disconnection ability. There are hundreds of different contact materials available that have been successfully used in many different applications. This article highlights three different categories of contacts commonly used in electrical equipment design: (1) Laminated Button Contacts, (2) Sintered Contacts, and (3) Metallized Carbon Contacts.

Laminated Button Contacts

Laminated button contacts, sometimes referred to as “clad metal contacts”, consist of two or more metal layers, ranging in material from fine silver to complex alloys. These layers are often bonded to each other by means of a cold-welding method called cladding. Put simply, cladding is a process by which dissimilar metals are joined under pressure to form a metallurgical bond. For button contacts, this process often involves bonding two or more form-rolled strips by means of heated compaction (see Figure 1). The resulting contact tape consists of multiple metal layers, each of which has specific material properties that are beneficial to the final product. For example, highly conductive precious metals like silver are often backed by stronger ferrous metals like nickel or steel, resulting in a contact that is both strong and conductive. Practically any combination of metals can be used to optimize electrical conductivity, strength, corrosion resistance, weldability, wear resistance, etc.

Figure 1: Bimetal or trimetal overlays from which clad contact tapes are produced are often form rolled, which allows the manufacturer to provide a wide range of weld projection surface designs on the contact tape.

In addition to optimizing certain material properties, cladding also allows for cost optimization. The amount of expensive precious metal in a button contact can be minimized by decreasing the thickness of the precious metal layer as much as possible without diminishing the conductivity of the contact below an acceptable level. Through tight control of layer thicknesses and regular quality inspection, electrical contact manufacturers have developed reliable processes that result in high quality contact tape with consistent properties. Once the contact tape is formed, the final step in producing button contacts is to coin the buttons from the tape. Any unused metal in the tape can then be recycled and recovered.

Even though contact manufacturers can tailor the material properties of button contacts for a specific application, these types of contacts are not suitable for all applications. They are typically reserved for relatively low power connections. Unlike most sintered contacts, button contacts often do not have a refractory metal in their composition, so they are less resistant to heat and wear. As such, button contacts are mostly found in relatively low power thermostats, light switches, and motor protectors where they will not be exposed to extreme voltage drops or temperature fluctuations.

Figure 2: Button contacts formed from contact tape often have weld projections on the non-contacting side to facilitate brazing to some type of backing.

Sintered Contacts

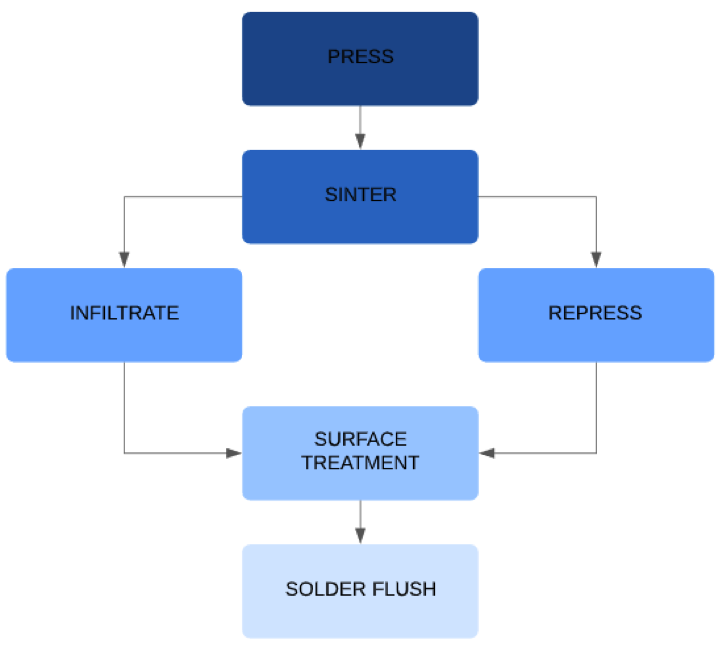

Sintered contacts are widely used for their versatility and durability in a variety of conditions. These contacts are commonly found in residential circuit breakers, electromechanical power switches, and medium to high voltage switchgear. Electrical contacts manufacturers have developed and optimized processes that allow for mass production of sintered contacts with consistent quality. Figure 3 shows a simplified process flow chart, depicting the general steps used to manufacture sintered contacts.

Figure 3: Generalized process flow for sintered contacts

Production starts with pressing a powdered metal blend into blanks, followed by sintering the blanks in an inert atmosphere. After sintering, the resulting material has much of the strength required of an electrical contact, but it has voids which must be removed. This can be done either by a re-pressing operation where the voids are physically collapsed, or by an infiltration operation where a molten metal fills the voids via capillary action. This results in a dense, void-free part that has both the strength and electrical conductivity required of an electrical contact. Next, the conductive surface can be treated to increase the amount of conductive metal (i.e. silver or copper) at the contact interface, allowing for a connection with less contact resistance and electrical noise. This can be done in several ways, depending on the constituents of the powdered metals in the contact. Finally, if a face of the contact is to be brazed to some type of backing, that face can be treated with solder to facilitate the braze.

Relative to button contacts, sintered contacts can operate in higher power applications without issue. This is in large part due to the presence of a refractory metal in the contact, since refractory metals are extraordinarily resistant to heat and wear. In general, sintered contacts consist of a refractory phase (like tungsten or tungsten carbide) suspended within a highly conductive metal matrix (like silver or copper). The exact constituents of the contact are highly dependent on the application.

Figure 4: Sintered contacts can be manufactured in a wide variety of shapes and sizes, depending on the application

Metallized Carbon Contacts

Metallized carbon plays a unique role in the electrical contacts world. This material combines the beneficial properties of carbon graphite with the useful features of conductive metals (usually silver or copper). The resulting material is ideal for high reliability relays and brushes where arc welding due to overload currents is a possibility. The major benefits of metallized carbon contacts are highlighted in Table 1.

Table 1: Benefits of Metallized Carbon/Graphite Contacts

Unlike button contacts and sintered contacts, the core matrix of metallized carbon is not metal, but rather carbon graphite. During production, metal is impregnated into the porosity of plain carbon graphite, resulting in a homogeneous distribution of metal throughout the material. Typically, metallized carbon graphite is about 15-65% metal by weight.

Metallized carbon contacts are common in many applications, including railway signaling, wind turbine slip rings, and imaging devices like CT scanners or X-ray detectors, to name a few. Across all these applications, arguably the most important feature of metallized carbon contacts is that they are fail-safe. If exposed to an overload current condition or excessive arcing, these contacts will not fuse shut since carbon graphite does not melt at elevated temperatures. This serves to prevent dangerous and potentially life-threatening situations.

Conclusion

When determining which type of electrical contact to use, it is important to consider all options that are available. Laminated button contacts, sintered contacts, and metallized carbon contacts each have their own advantages and disadvantages. There are plenty of online resources with relevant information for contact design. For additional guidance, get in touch with the experts at ECL.